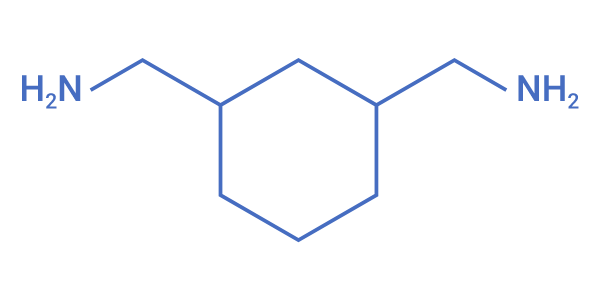

Structure and Features

✔High tensile strength ✔Stability ✔Water resistance

✔Yellowing resistance ✔Low viscosity + low melting point ✔Fast curing

1,3-Bis(aminomethyl)cyclohexane (1,3-BAC) is a diamine used primarily as an epoxy resin curing agent, but can also be used as a chain extender in polyurethane dispersions (PUDs) PUDs are used in many aspects of society, including in leather coatings.

Film Tensile Test

The addition of 1,3-BAC can increase the strength of urethane films.

The use of 1,3-BAC as a chain extender in PUD offers various advantages. For example, it improves the tensile strength and tensile modulus of the film compared to competitive products, resulting in a tougher film.

Storage Stability

The viscosity of polyurethane dispersions with 1,3-BAC does not change,

indicating good storage stability.

There is also an advantage to using 1,3-BAC with respect to storage stability when PUD is stored at elevated temperatures (50°C). Compared to competitive products, 1,3-BAC is superior in terms of storage stability, as there is no increase in the viscosity of PUD after long-term storage.

Chemical Resistance Test

Water resistance and chemical resistance of polyurethane films with 1,3-BAC are excellent.

The water and chemical resistance of PUD film is also highly effective when 1,3-BAC is used. While PUD film made with competing products bleaches when immersed in water, film made with 1,3-BAC shows no change, indicating that it exhibits high water resistance. Similarly, no change occurs when droplets of acid or alkali are left on the film, indicating that the film has high chemical resistance.

Example of Formulation

Synthesis procedure

- 1. IPDI (8.34 g), DMPA (0.94 g), PCD (20.98 g), methyl ethyl ketone (MEK, 10 g) and dibutyl tin(IV) dilaurate (0.02 g) are mixed and heated at 80°C for 4 hours.

- 2. Cool to room temperature and neutralize by adding triethylamine (0.71 g).

- 3. Neutralize by adding Pour slowly water (46.9 g) with vigorous stirring to make an emulsion.

- 4. Add 1,3-BAC (1.4 g) dissolved in water (10 g) to the emulsion.

- 5. MEK is removed under reduced pressure (350 hPa, 50°C, 45 min).

- 6. The following is an example of a synthetic formulation of PUD.

For example, we have also confirmed that 1,3-BAC can be effective even if some of the polyol components are replaced from the above formulation.

※PCD:Made by Asahi Kasei Corporation DURANOLT™

Other Applications

PUD applications are not limited to leather coatings, but are also used in nail polish and woodworking paints. Demand for PUD, which uses water as its main solvent, is expected to grow in the future in consideration of the enviromental impact of organic solvents.