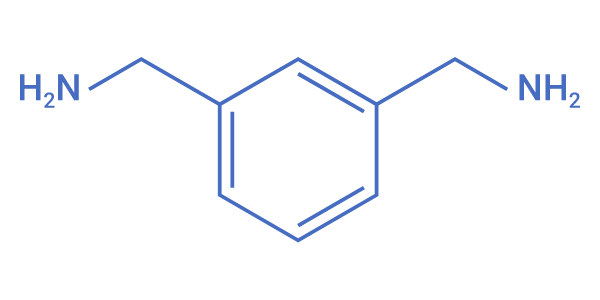

Structural Formula

MXDA adduct is an epoxy resin curing agent with fast curing and salt water resistance. NIKANOL Y-300 (xylene resin: NIKANOL®) can be added to epoxy resins to improve adhesion, flexibility, and water resistance.

Pot life can be extended by adding NIKANOL Y-300 to MXDA adduct. In addition, it reduces water absorption and further improves salt water resistance. The cured product can have both strength and flexibility.

Basic physical properties

Viscosity can be reduced by adding NIKANOL Y-300 to MXDA adduct (benzyl alcohol: 40wt%). Furthermore, when mixed with BisA epoxy resin, the maximum exothermic temperature can be reduced and the pot life can be extended, thus improving workability.

Coating film performance (23°C, 50%RH)

Comparison of coating film performance of BisA epoxy resin + MXDA adduct (BA: 40wt%) with 10 phr of BA or NIKANOL Y-300.Y-300-added products are flexible (Erichsen test) and adhere well. In addition, salt water resistance can be improved.

Mechanical Properties

Mechanical properties were measured using the same formulation; the addition of Y-300 provides elongation while maintaining strength, making it possible to achieve both strength and elongation.

Thermal Properties

Y300 addition can suppress the decrease in weight loss temperature and glass transition temperature(Tg) compared to BA addition.

Water Resistance and Water Absorption Test (23°C, 40 days)

Since NIKANOL Y-300 has high water resistance, the addition of Y-300 reduces the amount of water in the coating film. Furthermore, it is possible to make the cured product low water absorption.