Recommended formulation of Self-emulsifying Epoxy Resin Compositions

NIKANOL AM-2000 can be easily emulsified by hand without the need for special equipment.

This is a case study of a formulation using MXDA-based curing agent and the amphiphilic compound NIKANOL AM-2000 as a self-emulsifying epoxy resin compound. By mixing NIKANOL AM-2000 with the curing agent side of a two-component epoxy resin curing agent, an emulsion composition can be prepared simply by mixing with a hydrophobic bisphenol A liquid epoxy on the base resin side and adding water. Gaskamine-240 (G-240) and Mannich modified curing agents are suitable as curing agents.

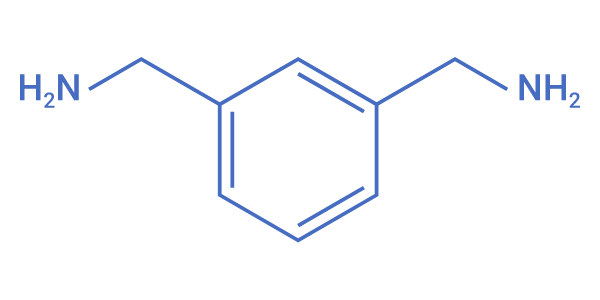

Structure of NIKANOL AM-2000 (emulsifier)

NIKANOL AM-2000 is a compound based on xylene resin to which a hydrophilic group is added.

This compound can be used as an emulsifier and contributes to emulsion stability and high performance of resin compositions because it also retains its properties deriving from the lipophilic group.

Appearance of Coating Film

By coating epoxy emulsions with NIKANOL AM-2000, a smooth coating can be obtained.

The emulsion composition of NIKANOL AM-2000 is stable, and a glossy coating can be obtained. On the other hand, if the same procedure is performed using general emulsifiers, stable emulsion compositions cannot be produced, and the surface properties of the coating deteriorate even if the emulsion compositions are coated.

Coating film properties

NIKANOL AM-2000 enables the use of MXDA-based modified curing agents as water-based curing agents,

and provides better coating performance than similar products.

In evaluations of water-based coatings using NIKANOL AM-2000 combined with a curing agent that is either G-240 or MXDA Mannich based, the performance of the coating such as hardness and water resistance is significantly better than that of competitors’ products. Therefore, the use of NIKANOL AM-2000 makes it possible to easily develop waterborne coatings with high performance.

Test Conditions

- Coating : Applicator (wet 100 μm (Mannich Modified MXDA) or 200 μm (G-240))

- Substrate: Zinc phosphate treated steel plate 150 x 70 x 0.8 mm

- Evaluation : Excellent (Ex)>Good (G)>Formal (F)>Poor (P)

- Pencil hardness : (Hard)2H>H>F>HB>B>2B>>6B(Soft)

Recommended procedure

- 1. Mix Type BisA liquid epoxy resin and curing agent (amine/AM-2000).

- 2. Add 30% of the water to be added to the mixture and stir for 2 minutes.

- 3. Add the remaining water to the mixture and stir for 2 minutes to obtain an emulsion.