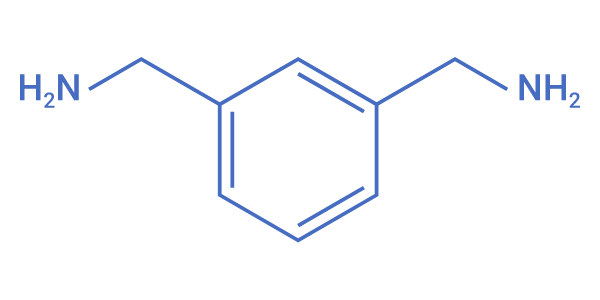

Structure and Features

✔Salt water resistance ✔Fast curing ✔Low alteration(carbonate)

MXDA has the characteristic of providing saltwater resistance when used as an epoxy resin curing agent. The saltwater resistance of offshore wind turbine blades may extend the repair period. In addition, it is expected to improve workability and productivity due to its fast curing and reduced stickiness of the coated surface.

Strength retention under saltwater conditions

Retains high adhesion in saltwater resistance. Suitable for construction of fiber reinforcement for offshore wind turbines, etc.

To simluate blade repair, a GFRP base was used as the blade body, and repair GFRP was laminated on top using various hardeners by hand layup method. When salt spray tests were conducted on the specimens, the adhesive strength of MXDA retained its strength, whereas that of common aliphatic amines decreased over time.

Hand layup molding

When repairing blades, since they are laminated by hand layup, surface quality is important and MXDA produces a clear surface, whereas common aliphatic diamines partially or totally whiten.

Resin condition after curing (23°C-50%RH, 15 hours)

During blade repair, workability is important. With general aliphatic amines, there is some surface stickiness even after 15 hours at 23°C/50%RH (the black area in the photo shows the sticky area). On the other hand, MXDA has no surface stickiness, indicating that it has cured sufficiently.

Saltwater Resistance Evaluation Formulation as Matrix Resin (35°C/1 month)

We found that replacing a portion of the matrix resin composition of GFRP in the blade body with MXDA can provide saltwater resistance. The addition of saltwater resistance to the blade body extends the blade life and maintenance period.

※D-230:Made by Huntsman JEFFAMINE ®

As blades become larger, epoxy resins are required to have a long pot life, and a composition with 10% MXDA can extend the pot life compared to conventional formulations. In addition, GFRPs with MXDA tend to have improved tensile modulus.