Epoxy resin is used as a resin binder for natural stone such as gravel in landscape pavements in tourist areas. By using 1,3-bis(aminomethyl)cyclohexane as a hardener for this resin binder, pavement materials with high strength, high water resistance, and high weather resistance can be produced.

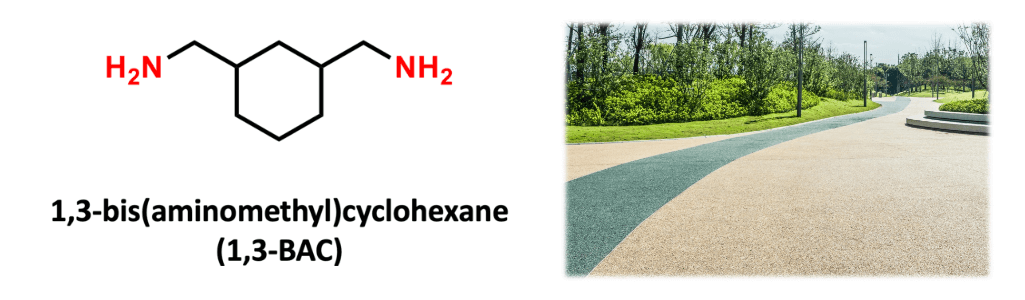

Bending strength

(aggregate:dry silica sand No.4)

Flexural tests were conducted on cured materials made by mixing 1,3-BAC and silica sand No. 4 in a silica sand/resin = 9/1 weight ratio, cured at 23°C/50%RH for one week, and flooded for another week. The cured materials showed higher strength after flooding compared to alicyclic amine and aliphatic amine from other companies. Thus, since cured 1,3-BAC exhibits high water resistance, it can be expected to suppress the strength loss of pavement materials due to rain and moisture.

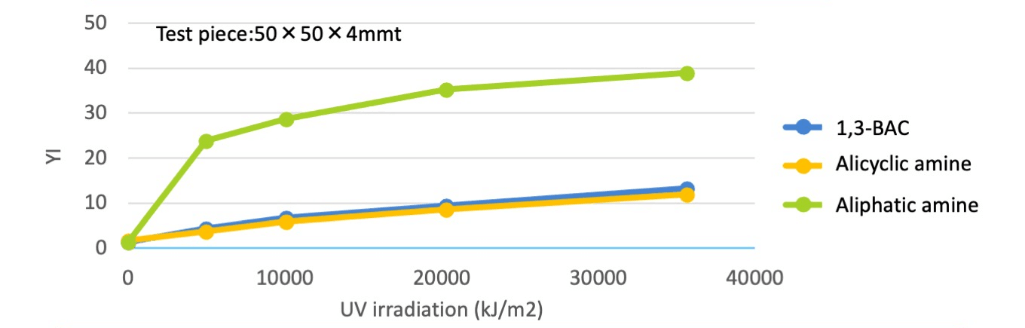

UV resistance test

(curing condition:23℃/50%RH、1week)

1,3-BAC is a weather-resistant amine. Pavement materials are affected by sunlight, which causes yellowing of resins due to UV rays. 1,3-BAC shows less yellowing due to UV rays than aliphatic amines, and can be expected to reduce resin coloration due to sunlight.

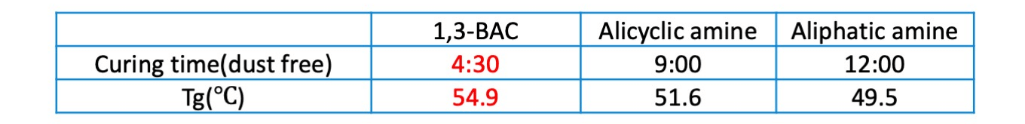

Coating properties without aggregate

(curing condition:23℃/50%RH/1 week)

1,3-BAC is a fast curing amine, curing faster than alicyclic and aliphatic amines. As a result, the curing period after paving can be shortened.