Gaskamine Grace (G-Grace)

Low skin sensitizing amine* (compared to typical amines**)

Good appearance (No Amine blushing)

Good water resistance in combination with benzyl alcohol

Good flexibility in combination with benzyl alcohol

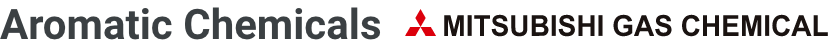

Gaskamine Grace (G-Grace) is a low skin sensitizer, making it a safer amine compared to other general-purpose amines.

When used as an epoxy resin curing agent, it inhibits the occurrence of brushing and exhibits good coating film appearance. Furthermore, by adding benzyl alcohol, water resistance and flexibility can be greatly improved.

*) Based on the results of skin sensitization test LLNA (based on OECD TG429)

**) G-Grace is classified as a mild sensitizer (general-purpose amines are classified as moderate sensitizers).

Basic Data

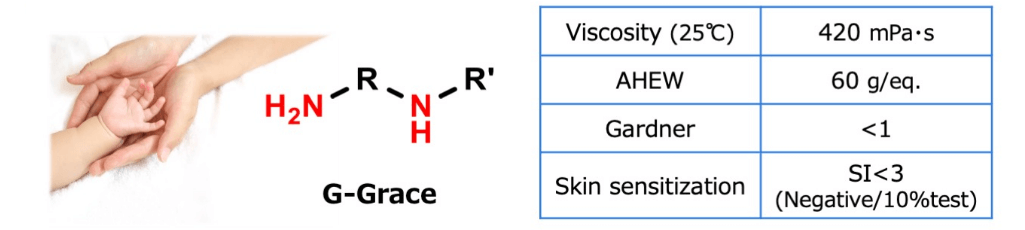

Pot-life・Tg

jER828:jER® by Mitsubishi Chemical

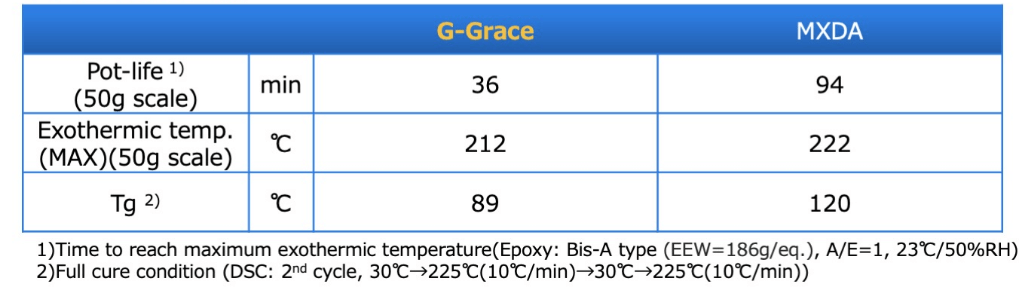

Appearance -23℃/50%RH

Gaskamine Grace can be used to produce a good glossy paint film without amine brushing.

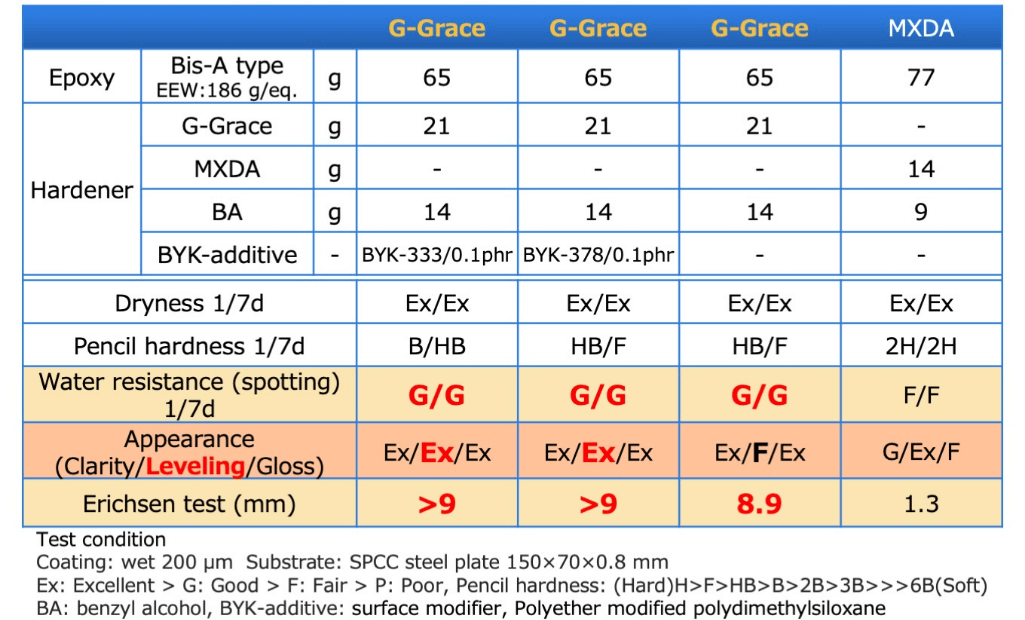

Formulation to add Benzyl Alcohol

Curing properties -formulation to add benzyl alcohol 23℃/50%RH

Gaskamine Grace, when used in combination with benzyl alcohol, exhibits good coating film appearance and also has good water spot resistance. In addition, Gaskamine Grace is a flexible coating film with high elongation.

Furthermore, smoothness can be improved by adding a surface conditioner.

1) BYK-333: BYK-Chemie

2) BYK-378: manufactured by BYK-Chemie

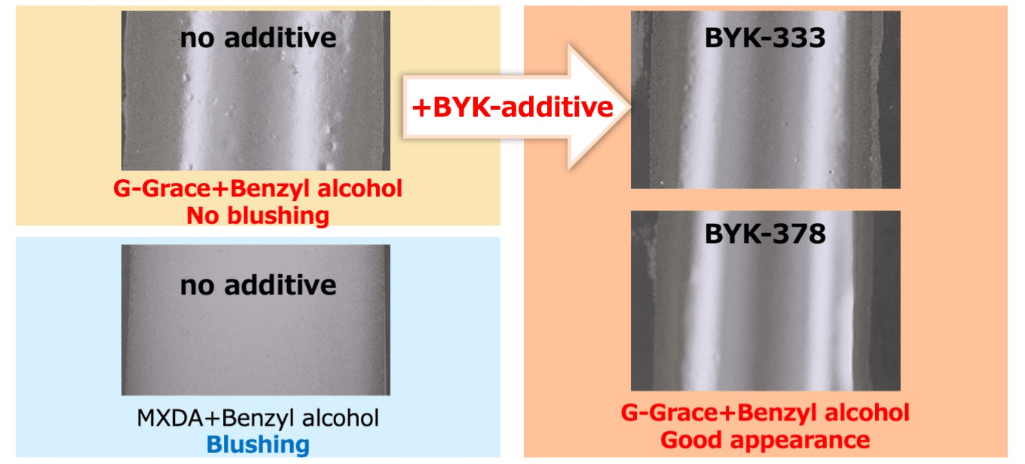

Appearance -formulation to add benzyl alcohol 23℃/50%RH

The formulation with Gaskamine Grace and benzyl alcohol produces a good glossy paint film without amine brushing. Furthermore, the addition of surface modifiers such as BYK-333 and BYK-378 improves smoothness and provides a good coating film appearance.

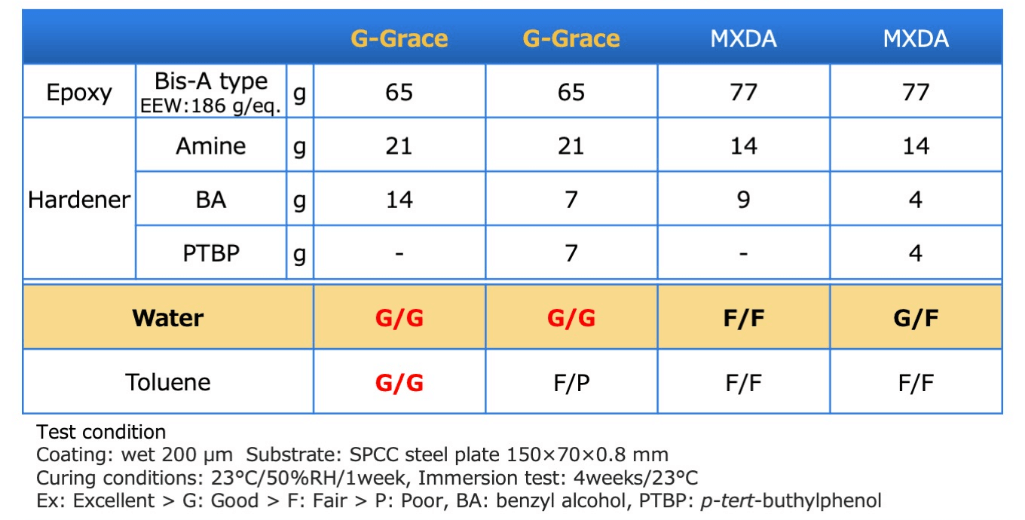

Chemical resistance -formulation to add benzyl alcohol 23℃/50%RH

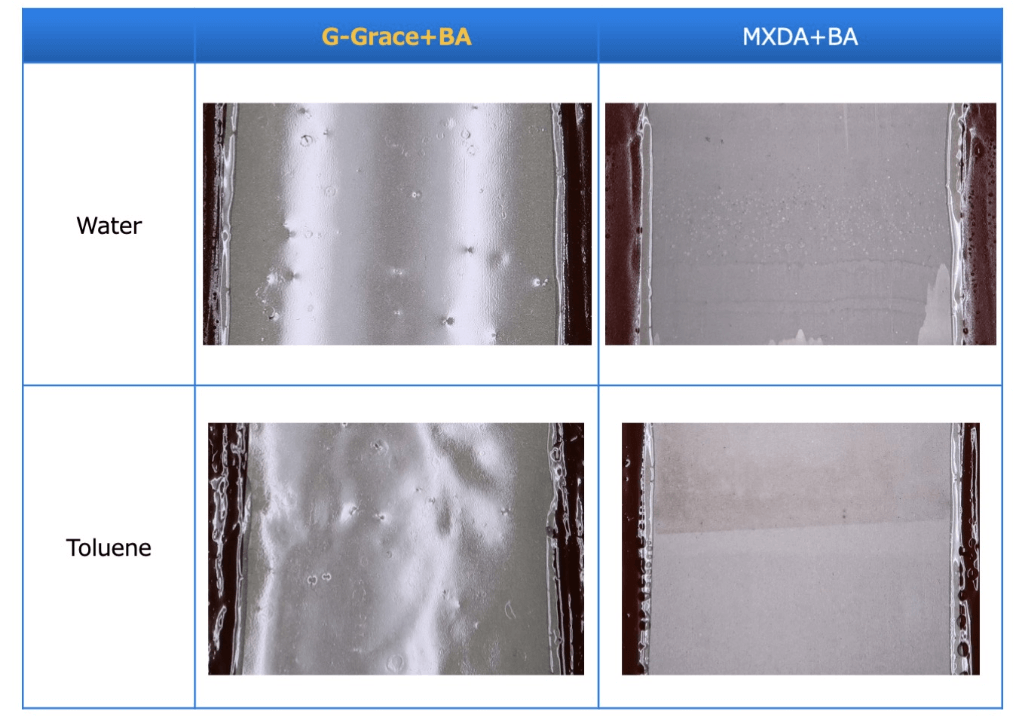

Combination formulations of Gaskamine Grace and benzyl alcohol give good results in water and toluene resistance.

You can see that the appearance of the coating film after the chemical resistance test is shinier than that of the MXDA formulation, even after the water and toluene resistance tests.

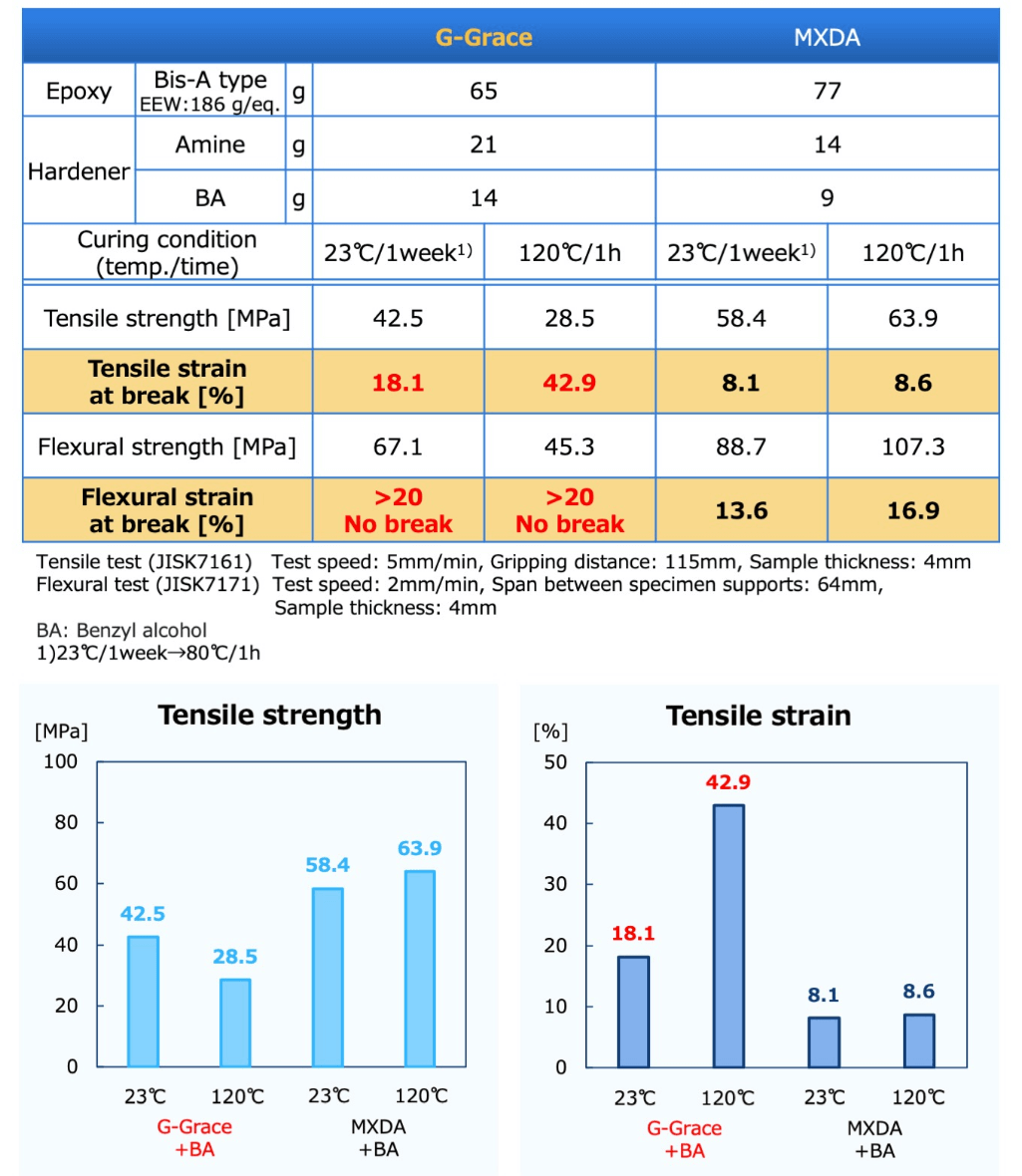

Physical characteristics -formulation to add benzyl alcohol

Measurements of the mechanical properties of the resin moldings showed that despite the epoxy resin, the moldings were extremely flexible with high tensile and flexural strains.

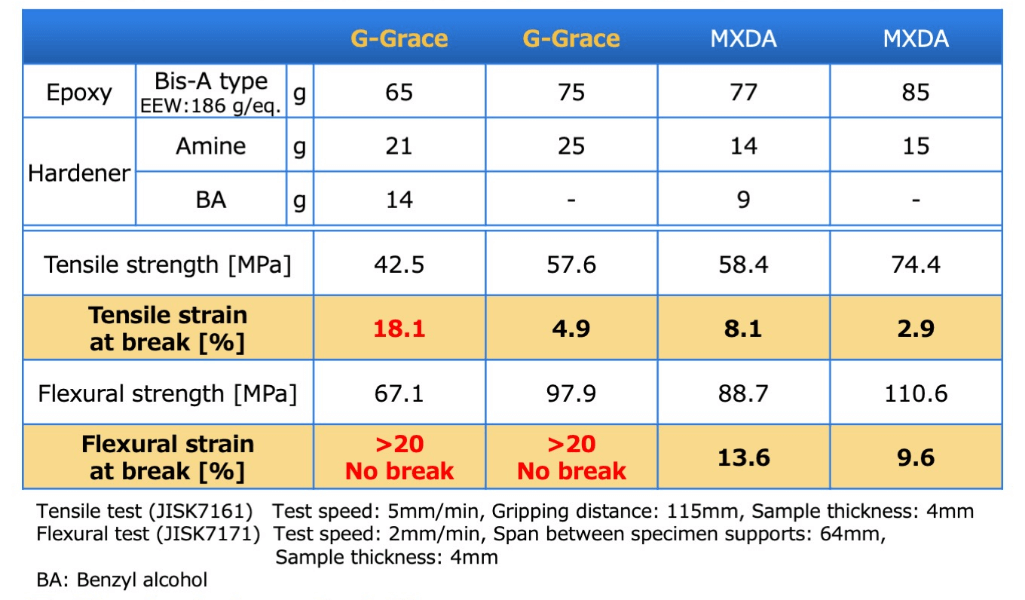

Physical characteristics -23℃/1week –Adding BA vs without BA

The flexibility of the molded resin body after curing at 23°C/50%RH for 1 week was compared with and without benzyl alcohol (BA), assuming room temperature curing.

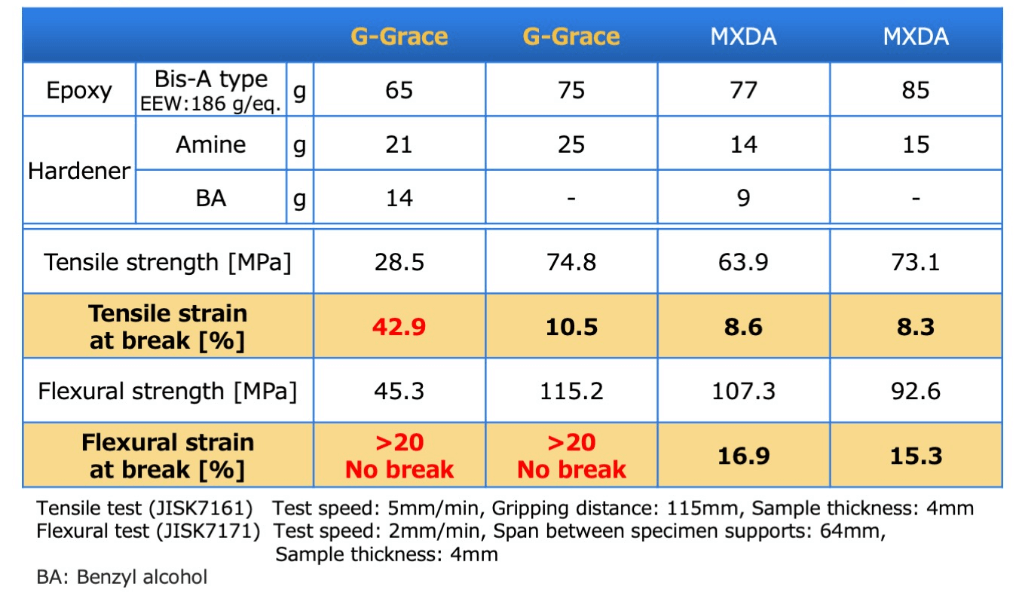

Physical characteristics -120℃/1h –Adding BA vs without BA

Assuming heat curing, we compared the flexibility of resin moldings with and without the addition of benzyl alcohol at 120°C/1 hour curing.