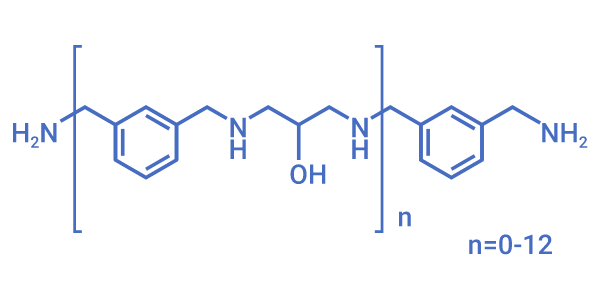

About G-328 Features

✔No VOC content ✔Water soluble ✔Low viscosity

✔Fast curing ✔High corrosion resistance ✔Low Phr

Gaskamine 328(G-328) is an oligomeric polyamine made from MXDA and is suitable for two-component waterborne epoxy resin coatings because it contains no VOCs and is water soluble. G-328 is also highly effective in terms of chemical resistance.

About Phr for Coating Waterborne Epoxies

G-328 requires a smaller amount of additive than typical waterborne curing agents.

G-328 has a very small Phr (additive amount per 100 parts of base resin), and the difference is obvious when compared to competing products, contributing to overall coating cost reduction.

Salt spray test (3 weeks)

The use of G-328 provides higher corrosion resistance than general waterborne curing agents.

Coating films of waterborne epoxy resin using G-328 as the curing agent exhibit high corrosion resistance. In a continuous salt spray test with incisions made in the coating film, rust formation from the incisions was suppressed even after 3 weeks, indicating that the coating film exhibits high resistance to salt water.

Properties of G-328

Viscosity can be adjusted to any desired level by water dilution.

The viscosity of G-328 can be easily adjusted by water dilution. In its undiluted state, the viscosity is about 8,600 mPa-s, but it can be lowered to less than 100 mPa-s by increasing the amount of water added.

Formulation of Coatable Waterborne Epoxy

Method of making Coatable waterborne epoxy

- 1. Mix all materials except waterborne epoxy with a paint shaker for 1 hour to make a pigment paste.

- 2. Pour the waterborne epoxy slowly into the prepared pigment paste and mix with a disperser.

The following is an example of mixing pigments and epoxy resin on the main pigment side. A pigment-dispersed paste is prepared using a paint shaker and mixed with a solid epoxy dispersion.

※ CR-97:Made by ISHIHARA SANGYO TIPAQUER ®

BYK-2081:Made by BYK-Chemie

AQ-530S:Made by Kusumoto Chemicas DISPARLONR ®

About Coating Film Physical Properties

Low Phr provides excellent cost advantages.

The following table compares the coating film performance of G-328, a curing agent, and a competitor’s product using the same base compound. Compared with competitive products, G-328 is superior in terms of low Phr, high hardness, and high corrosion resistance.

Heat Curing Characteristics

G-328 exhibits excellent performance in heat curing.

Waterborne epoxy resin coatings using G-328 are also suitable for heat curing, and can develop sufficient pencil hardness in 20 minutes under 80°C conditions. Furthermore, it is possible to obtain a coating film with high water resistance and salt water resistance.

Formulation with small amount of G-328 added (clear evaluation)

The addition of G-328 not only speeds up the rise in pencil hardness,

point rusting can also be suppressed.

G-328 can also be used as a modifier. For example, by replacing 5% of another company’s curing agent, pencil hardness and anticorrosion properties can be improved.

Troubleshooting

1. shelf life of G-328 aqueous solution

G-328 can be diluted with water, but if a large amount is added, separation may occur after long-term storage. For example, if G-328/water = 2/8 is mixed, precipitation will occur after 3 months, but adding a co-solvent such as propylene glycol methyl ether will prevent precipitation.

2. prevention of whitening of the paint film

Depending on the type of solid epoxy dispersion combined with G-328, the coating film may whiten. In such cases, adding a small amount of a film-forming aid such as propylene glycol propyl ether as a film-forming aid can inhibit whitening.

3. adjustment of pot life

To extend the pot life of two-component waterborne epoxy resin coatings using G-328, it is possible to extend the pot life by adding an appropriate amount of a co-solvent such as propylene glycol methyl ether.