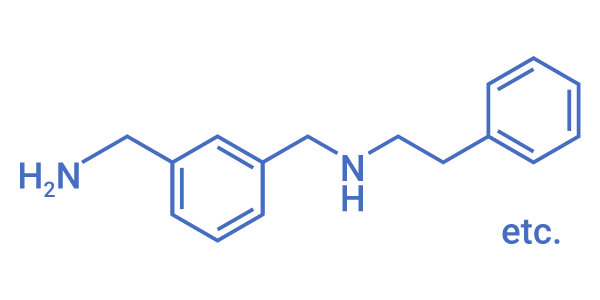

Epoxy resins are used as resin binders for natural stone such as gravel in landscape pavements in tourist areas. Since Gaskamine 240 (G-240) is a hydrophobic amine, it can be used as a curing agent for this resin binder to produce a hardened product even with water-containing aggregate. Furthermore, pavement materials using G-240 exhibit high strength and high water resistance.

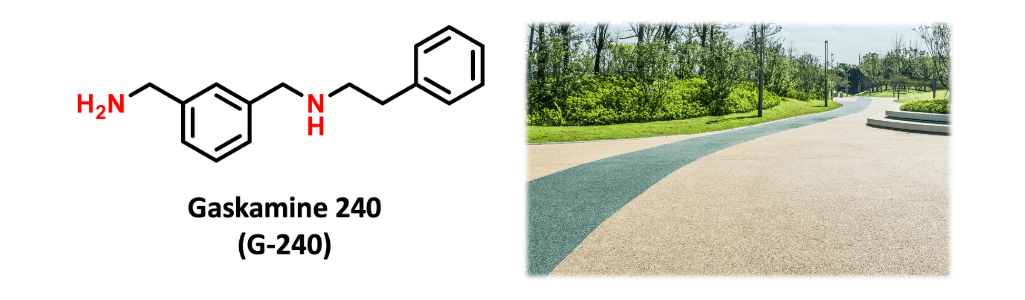

Bending strength

(aggregate:wet silica sand No.4 (water content ; 20wt%))

Since G-240 is insoluble in water, it can be used with wet aggregate to produce a hardened product. When G-240 is used as an aggregate with a moisture content of 20 wt%, it is possible to produce a hardened product with strength equivalent to that of dry silica sand. Cured products could not be prepared with alicyclic amines or aliphatic amines.

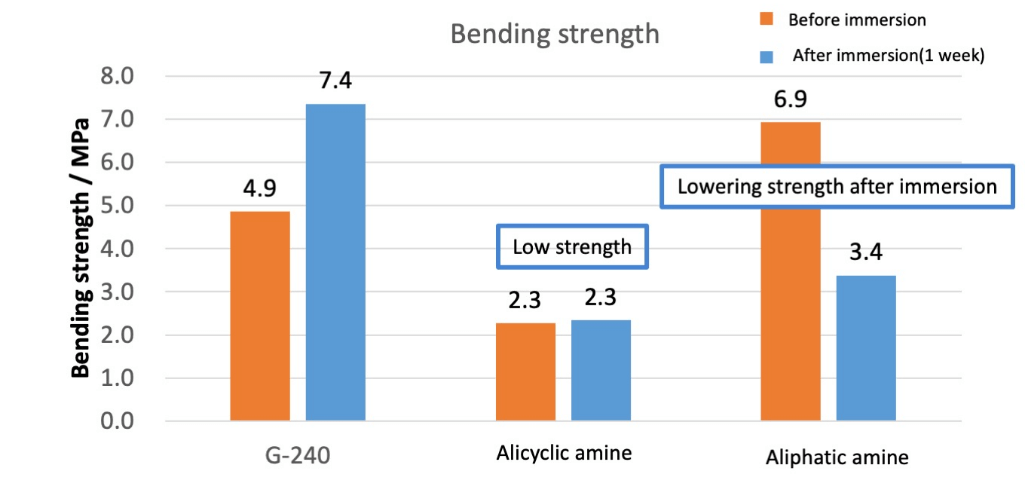

Bending strength

(aggregate:dry silica sand No.4 (water content : 0.2wt%))

A hardened mixture of G-240 and silica sand No. 4 in a silica sand/resin = 9/1 weight ratio was prepared and cured at 23°C/50%RH for one week, and a flexural test was conducted on the mixture that was flooded for another week. The mixture showed higher strength after flooding compared to alicyclic amine and aliphatic amine from other companies. Thus, G-240 exhibits high water resistance, which prevents the strength loss of pavement materials due to rain and moisture.

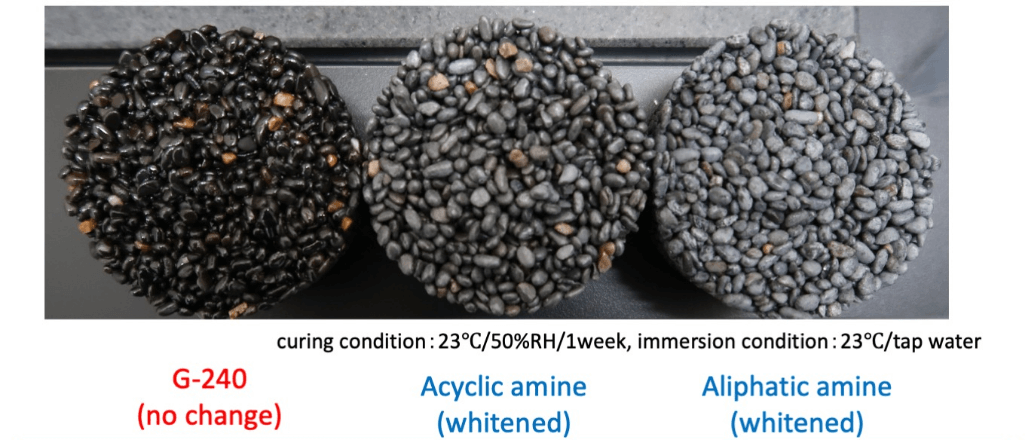

Appearance after water immersion for 1 day

(aggregate:black gravel)

Because G-240 is a hydrophobic amine, its cured product exhibits high water resistance. When cured material made of black cobbled gravel aggregate was immersed in water for one day, alicyclic amine and aliphatic amine cured material turned white, whereas G-240 showed no whitening, thus preventing appearance deterioration due to rain and other effects.

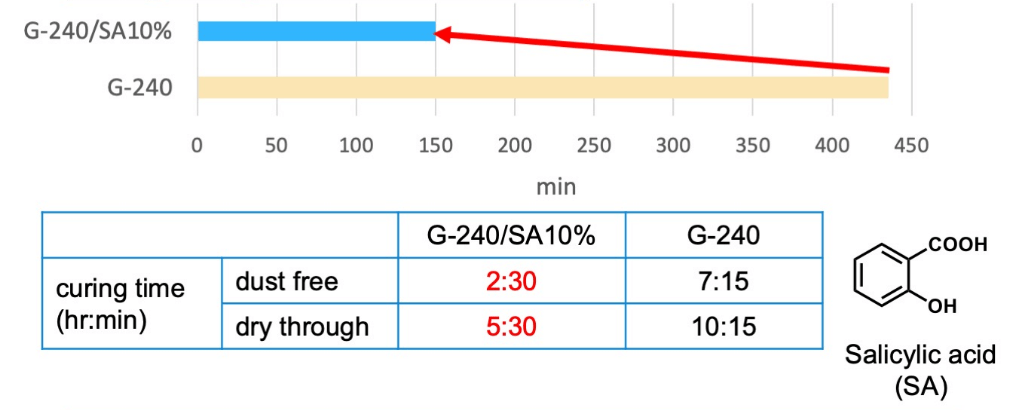

Curing time (dust free)

For resin binders for pavement materials, fast curing is important to shorten the curing period. 10wt% salicylic acid can be added to G-240 as a curing accelerator to shorten the curing time (G-240/SA10% formulation).

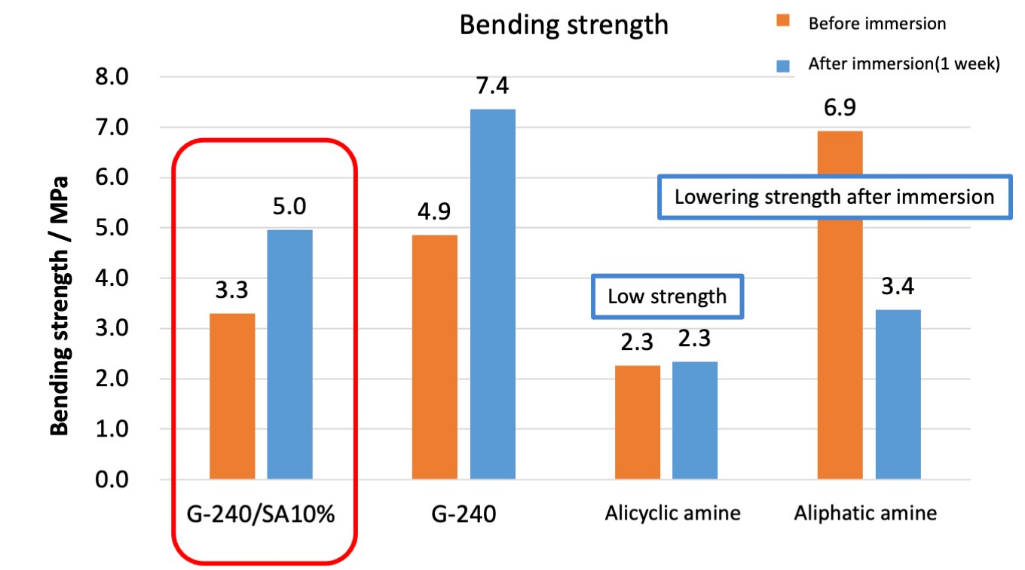

Bending strength

(aggregate:dry silica sand No.4 (water content : 0.2wt%))

Even when using the G-240/SA 10% formulation, it shows higher strength after flooding than the alicyclic and aliphatic amines of other companies.